Bacterial cellulose is a natural, pure form of cellulose made by special bacteria that turn sugars into tiny fibers, creating a strong, gel-like material.

Bacterial cellulose is superior in packaging because it is biodegradable, highly durable, flexible, and can be engineered for sustainable, plastic-free solutions with excellent moisture resistance and strength.

A shape-memory biomaterial created by combining bacterial cellulose (BC) with other biopolymers. This composite responds to stimuli like temperature or moisture, allowing it to return to its original shape while remaining biocompatible and biodegradable.It also has oil adherence capacity which is useful for oil spill cleanup.

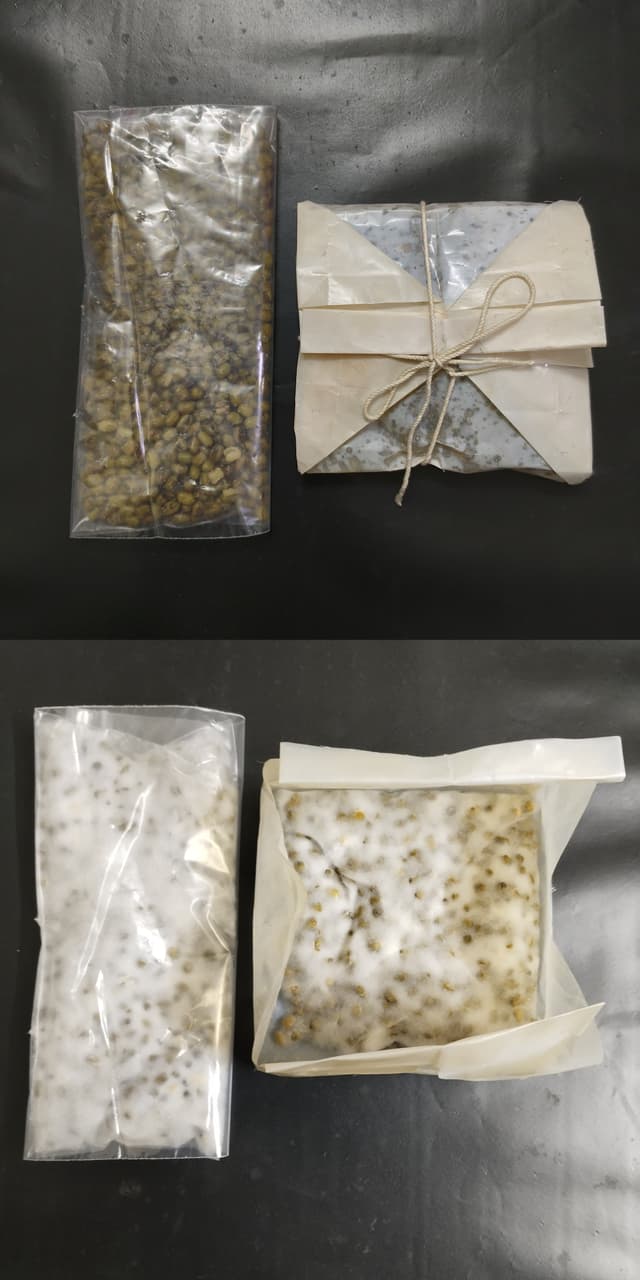

A customized bacterial cellulose packaging for tempeh can be designed as a breathable, biodegradable film or pouch that maintains freshness, prevents contamination, and allows natural fermentation while eliminating plastic waste.

Bacterial cellulose can be customized into eco-friendly packaging by adjusting its thickness, flexibility, and barrier properties to create biodegradable films, coatings, or structural materials that replace plastic.

A comparative prototype design for tempeh packaging features a conventional plastic pouch with airtight sealing versus a biodegradable bacterial cellulose pouch that is breathable, eco-friendly, and supports natural fermentation while reducing waste.

A straw made of modified bacterial cellulose sheets is biodegradable, durable, and water-resistant, offering a sustainable alternative to plastic straws. It maintains structural integrity in liquids while being eco-friendly and compostable.

A biodegradable, breathable bacterial cellulose pouch designed for tempeh, featuring a semi-transparent, eco-friendly structure that supports natural fermentation while protecting freshness and reducing plastic waste.